Introduction

Operating in an energy-efficient, and environmentally optimized manner is easier said than done. The traditional methods of controlling a pipeline do not consider the vast array of variables that contribute to the bottom line and provide no method of tracking the improvements made.

Using data analytics, mathematical optimization, and detailed knowledge of a pipeline, Venturi has developed a method to assist operators in advancing to this optimal state. In addition, our optimization software provides systems analysts with the tools to verify the improvements that have been made in:

- Power savings

- Pump and Drag Reducing Agent (DRA) cost savings

- Emissions savings (metric tons of CO₂)

- Operator effectiveness

What Factors are Considered?

Venturi’s power optimizer is built on a mathematical model that considers all of the following:

- Pipeline profile, and real time data

- Pump and valve characteristics, as well as control philosophies

- DRA injection scheduling

- Power contracts by pumping station

- Emissions profile by pumping station

- Historical supervisory control and data acquisition (SCADA) information

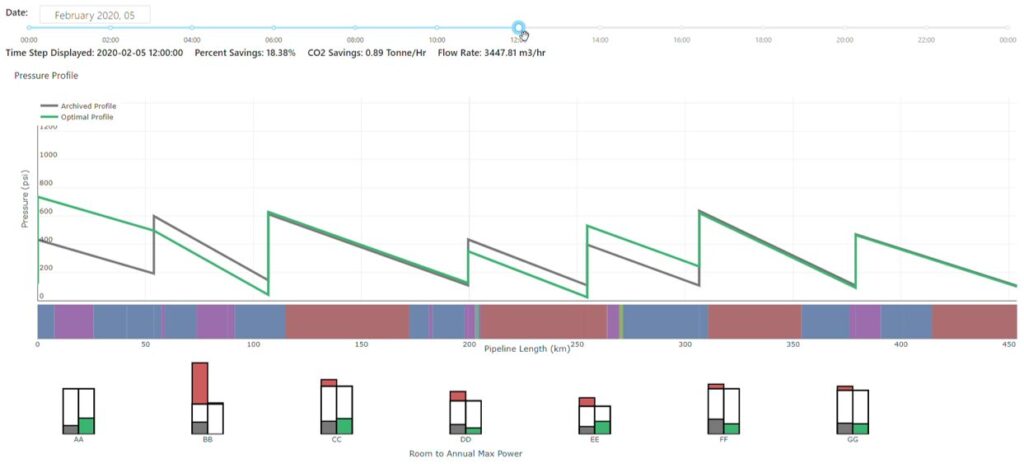

Based on these factors, the model compares with the current pressure profile of the pipeline, and provides the operator with an optimized pressure profile dashboard that will minimize overall system costs, with consideration for the overall costs of carbon emissions.

What Are The Results?

Based on analysis of real-world historical data for a major pipeline operator, Venturi estimated significant savings on all fronts, with a net reduction of operating costs of ~5% compared to true historical operation. In some cases, savings have the potential to be much higher due to reduced annual maximum power demand (spikes that impact semi-fixed cost year-round) or to modify DRA usage from typical manufacturer recommended best practices.

How Is This Implemented?

While the optimizer has not been fully implemented in a pipeline (to date), the planned implementation of Venturi’s power optimization is rolled out through several stages, in collaboration with our clients. As the system has to integrate closely with each client’s data acquisition system, the platform is customized to best meet the needs of a specific control room and pipeline. After modeling pipeline profile, pump/valve curves, and energy sources, real data validation is performed to assess the optimization potential for a given system. Following this assessment, a controlled pilot and client platform integration may be performed.

Given the significant energy and environmental savings, an efficient rollout is of the highest priority to Venturi.

Closing

As described above, Venturi’s power optimizer model can provide significant benefits to both operator and energy analyst, ensuring a pipeline is being operated in the most cost and energy efficient manner. The investment Venturi has put into this project is a testament to the potential we see in it, both for our clients and the planet. To learn more, contact us today.